The US Department of Energy (DOE) Vehicle Technologies Office has announced the selection of five industry-led research and development projects to develop lightweight materials to improve the energy efficiency of electric vehicles.

According to the DoE, these projects will help decarbonize the transportation sector and enhance the infrastructure needed to support the growing adoption of zero-emission vehicles. Furthermore, the award recipients will also be allowed to join the Lightweight Materials Consortium, or ‘LightMAT’, to help “accelerate solutions to the nation’s toughest materials challenges in the energy sector”. So far, the LightMAT consortium comprises a network of 11 national laboratories “with technical capabilities highly relevant to the development and commercial use of lightweight materials and manufacturing processes”.

The selected projects will benefit from financial support of up to $500,000, as well as technical assistance from the partnering national laboratory, over a maximum project runtime of 2 years.

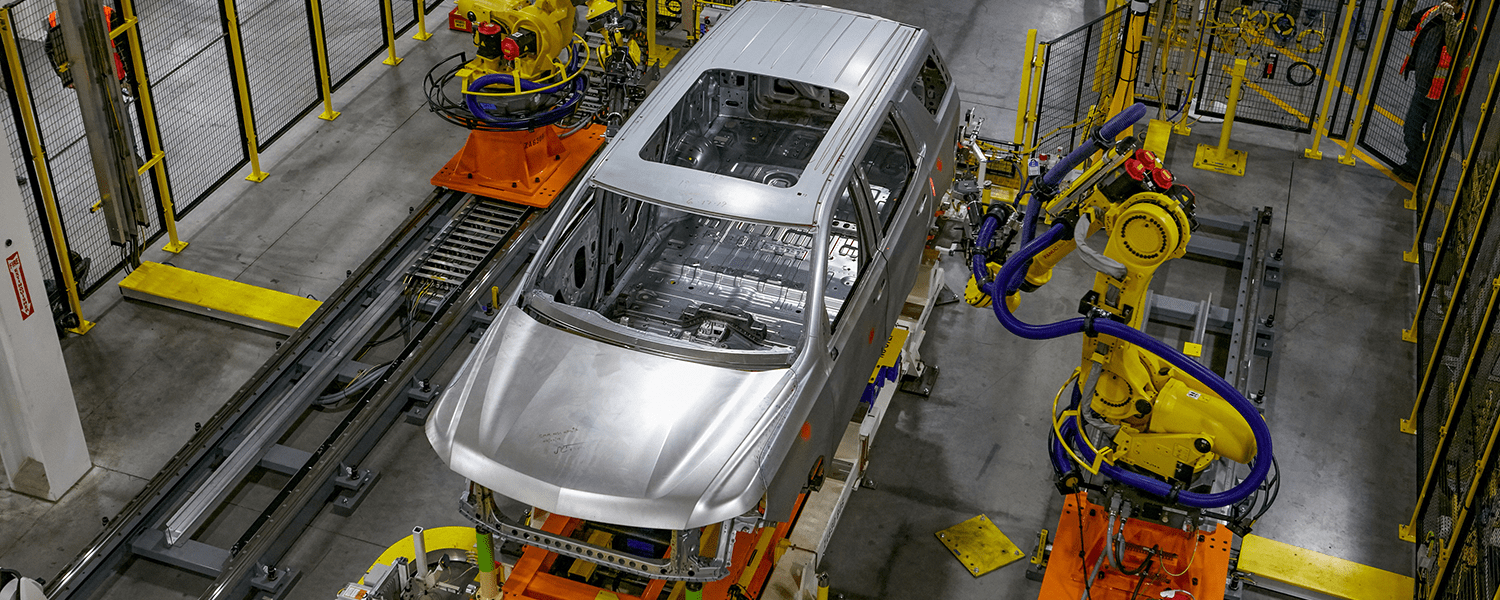

The five projects that were selected for this year include three being run by General Motors, titled ‘Atmospheric Plasma Deposition for Adhesive Bonding of Multi-Material Systems’, ‘A Machine Learning Assisted Weld Quality Diagnostic Tool to Assure Structural Integrity of EV Battery Enclosure’, and ‘Development of Sustainable Aluminum Alloy for Lightweight Ultralarge Castings’. The projects will be carried out at the Oak Ridge and Pacific Northwest National Laboratories.

The other two participants are Vehma International and Dow Aksa, who are working on the ‘Direct Extrusion of 6082 and 7xxx Battery Tray Structures Using Shear Assisted Processing and Extrusion’, and ‘Wholly Sustainable, Cost-Effective Carbon Fiber-Nylon Compounds’, respectively. Both of these will be done at the Pacific Northwest National Laboratories.