In 1941 labor leader Walter Reuther asked automotive CEOs and national leaders to trust the United Auto Workers to supply American troops with planes and tanks. After Pearl Harbor, Detroit became the “Arsenal for Democracy” by fighting nazis via assembly line production.

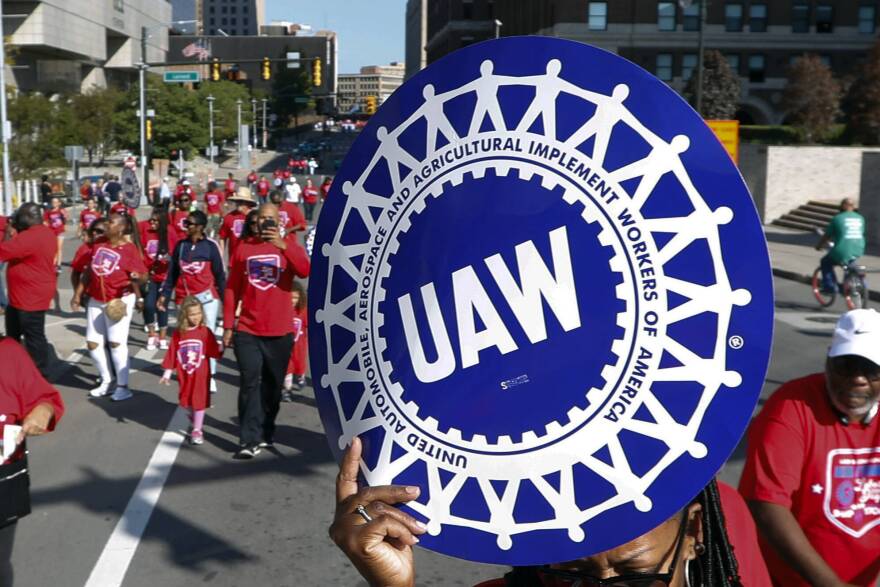

Now, 82 years later, the UAW is looking for the same confidence to mainstream electrification.

“Our people converted from automobile production to war production in every plant, and it was done in 90 days. We can do the same thing with electric vehicles,” Earl Fuller Jr, the UAW Local 160′s General Motors unit chairperson and part of the national bargaining committee, said ahead of negotiations in July.

The union’s role in electrification is a strong undercurrent in the UAW’s contract negotiation with the Big Three, which ends at 11:59 p.m. Sept. 14.

For workers it’s a matter of job security. For the automakers it’s about profit margins.

“It’s a nightmare time for this to happen with automakers in the 313 area, making the aggressive move to electric vehicles,” said Daniel Ives, managing director and senior equity research analyst at Wedbush Securities, a California-based investment firm. “It’s really created a game of thrones battle with a ripple impact that could be seismic, not just in Detroit, but across the country, if a strike ultimately happens.”

Many have compared the transition to electric vehicles as being as paramount as the introduction of the Model T. But the auto industry is becoming crowded with tech giants and automation.

The balancing act is keeping union workers firmly planted on assembly lines while keeping pricing competitive enough that the electric vehicles in driveways are American brands.

EV Battery Plants in union limbo

Battery plants are a grey zone in the auto industry because they’re joint ventures with tech companies.

General Motors’s Ultium Cells is a partnership with LG Energy Solution.

Ford’s BlueOval SK is a marriage of Ford and South Korea’s SK Innovation.

Stellantis is working with Samsung SDI for its battery plants.

Because these battery plants are not wholly owned by the Detroit Three, their workforce, even if its UAW, is not covered by the national contract currently being negotiated. The UAW calls this “legal fiction.”

Battery plant unionization is not a sticking point in negotiations, but it can’t be ignored either, said a source familiar with negotiations but not authorized to speak publicly. “Just as Toyota looms large in the back of members heads, the joint ventures loom large in the backs of members heads and their position in this industry.”

The union has been supportive of electrification, but UAW President Shawn Fain has called for a “just transition,” pointing to automakers trimming jobs as they head into an expensive decade.

The UAW had a recent victory in Lordstown, Ohio, where UAW battery plant workers ratified an interim agreement with General Motors that earned them an immediate $3 to $4 hourly increase. The UAW had previously targeted Ultium Cells and accused them of an unsafe working environment and ‘poverty wages.’

Wages in the battery plant sector lag those in traditional automotive assembly by almost a third, according to a report from the World Resources Institute, a nonprofit focused on environmental issues.

Battery plants are seen as the future power train. A traditional internal combustion engine requires about 200 individual parts. Powering an electric vehicle will take about 20 parts.

“One of the key things the union wants is job security,” said Michelle Krebs, Cox Automotive executive analyst. “They’re concerned that the transition to EVs will not require as many workers and that workers at the joint venture battery plants aren’t all necessarily represented by the union.”

Competitive pricing with non-union automakers

Competitors Tesla and Rivian are not represented by the union, meaning their labor costs are lighter.

Labor makes up about 7 to 8% of car prices, estimates John Taylor, a tenured associate professor of global supply chain management at Ilitch School of Business within Wayne State University.

The UAW estimates labor cost to be about 4 to 5%. The UAW’s economic demands included a 40% wage increase over the contract duration, mirroring that of the CEO’s wage increase over the last four years.

The Big Three’s slipping share of the market puts them in a vulnerable position for negotiations, Taylor said. Tesla retained its number one position for top EV sales in the second quarter with Chevrolet at a distant second and Ford in third place.

“They’re not in the same kind of dominant position they were back years and years ago when they kind of were the market,” Taylor said. “That means they have less ability to just agree to any old wage increase or increase in costs because many of their competitors aren’t going to be subject to those costs.”

How could a strike impact EV production?

If a strike happens and stretches into months then in-progress electric vehicle production, especially of new models, could be impacted, Ives said.

“This could push out electric vehicle roll outs for Ford and GM by three, six, even nine months depending on how long strike goes,” he said.

Electric vehicle inventories have been substantially higher than their gas counter parts. In late June, the days’ supply of EVs was over 100, whereas industry-wide inventory levels were closer to 53 days, according to Cox Automotive.

This high inventory is a sign of consumer interest plateauing, said Joe McCabe, CEO and President of AutoForecast Solutions.

The industry is still building a case for electric vehicles as a concept. As McCabe puts it, the early adapters have already embraced the EV lifestyle.

“The sheer slowing down of electrification is not going to be a result of strikes,” he said. “It’s going to be a result of market conditions, [buyers] not accepting them at the pace they were accepted at their early adopter phase.”

A September J.D. Power report showed EV adoption is still on the rise, but largely out west. Michigan, the auto capital, was among the bottom ten states ranked by adoption rates.

Nationally the report predicts EVs will make up 70% of market share by 2035. Meanwhile Michigan will only reach 41% market share by 2035, according to J.D. Power.

Cox Automotive’s July report stuck to its original forecast of one million new electric vehicle sales nationwide. It’s June survey of consumers found 50% are interested in EVs, but notes “being interested is easy, of course, but far fewer people actually buy.”

When that shift from looking to buying will actually happen is the elephant at the bargaining table, said Krebs, Cox’s executive analyst.